3D instead of 2D

At a Penthouseconversion in Vienna the overall complexity and weight of the structure and therefore its cost has been reduced significantly. Overall 5 Tons of Steel and many hours of planning, drawing and welding have been saved. A relatively simple attic conversion was built on a corner house in the 9th district of Vienna. Only part of it was extended with a second attic floor, while the rest was used as a roof terrace.

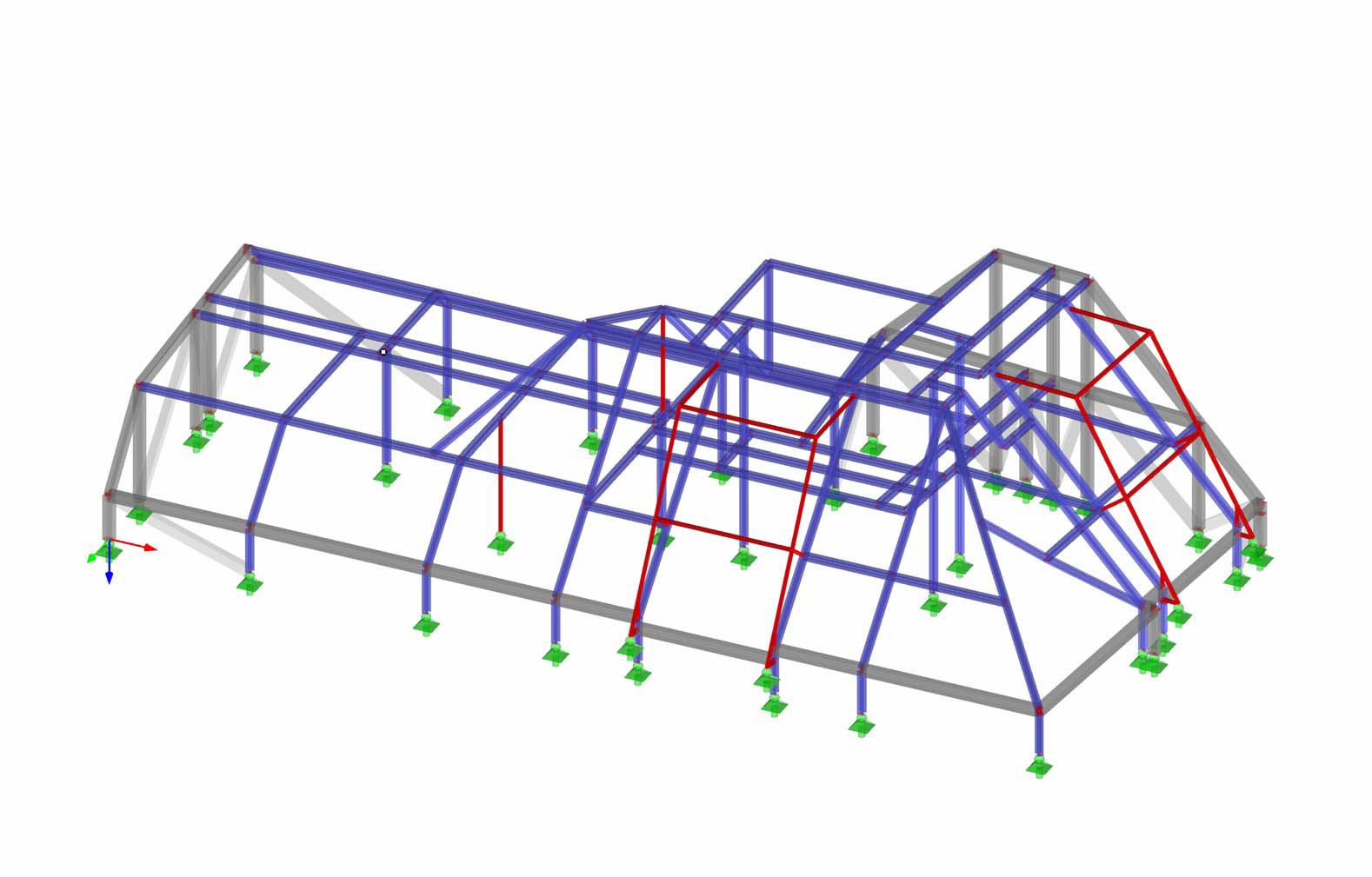

The original Structure was calculated in 2011 with the very same Software in the very same version that I have worked on this project. The essential difference was that the previous engineer had calculated all the frames in 2D, whereas I modelled the whole structure in 3D. For better comparison of the two structures i also made a 3D model of the originally calculated steel profiles.

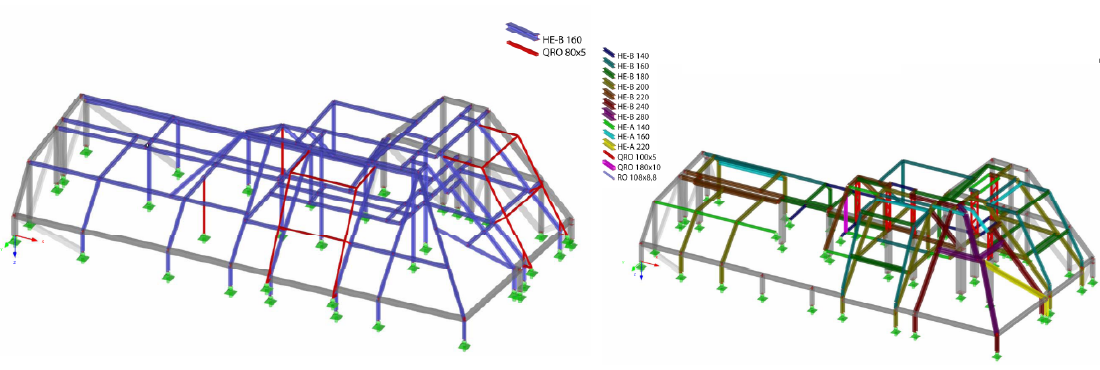

The Original Structure

The original structure had quite a few errors, not in respect of the static calulus but rather in respect of the customers greed. A rising complexity of a structure and the amount of different types of profiles that are used, can result in significantly higher costs for the whole project. Every engineer that wants to see his ideas realized, is strongly advised to have the abilities of the executing construction company in mind, even at a stage of planning when the contractors can not be known.

Assumably to minimize calculations only 3 frames and 4 beams were calculated. This resulted in quite high spans of 7m, a huge variety of 12 different types of HE-B steel profiles and therefore many different junctions and joints. Even if the base area of this penthouse was one of the smallest i had seen over the years the total weight of the steelframe construction was immense.

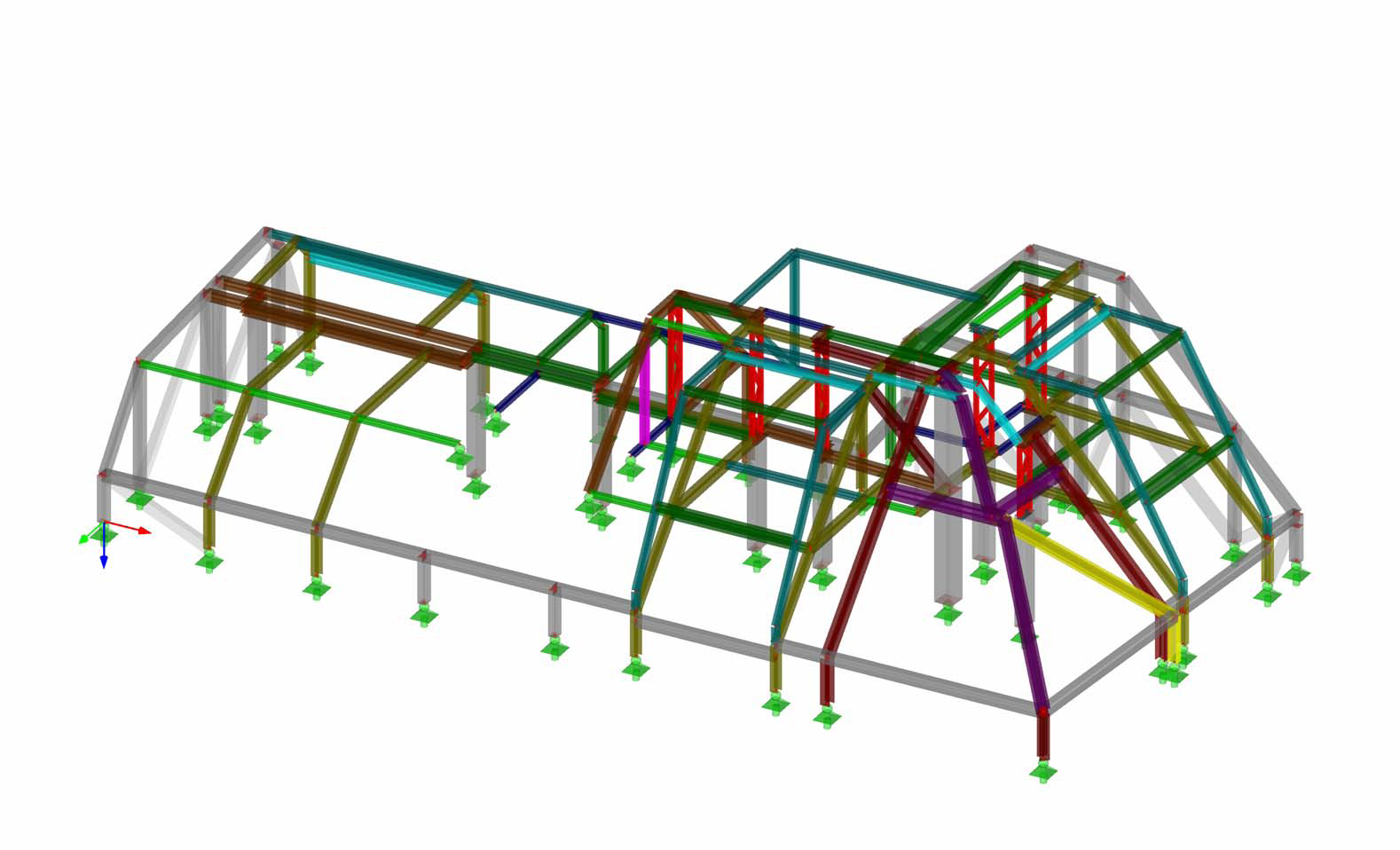

More Frames Less Steel

To make the structure more feasible quite a few changes were made. Additional frames reduced the span and neighbouring frames were connected horizontally. The quite complex columns at the central wall, that had a reinforced concrete part in the first penthouse floor and a framework of quadratic HSS above, were replaced by HE-B columns.

With all this changes 5 tons of steel were saved even if the total length of all steel bars was slightly increased. Only one type of HE-B profiles and one type of HSS profiles were needed. This especially reduced the different tyes of junctions and joints and simplified the work of both the draftsmen as well as the contractors because the amount of different plans and drawings was reduced significantly. Furthermore the intentions of the architect were met far better, because there were no additional supports in between the roof and the gallery needed.

English

English  Deutsch

Deutsch